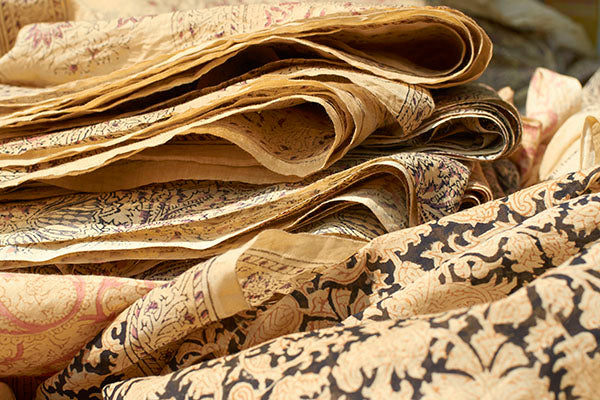

See The Kalamkari Block Printed Textiles

Kalamkaris are mordant dyed cotton plainweaves. Centuries ago, the dyes, mordants, or resists were applied through the time-consuming use of a pen. The term "kalam" means "pen" and "kalamkari" means "penwork."

The mordant-dye technique resulted in brilliant, fast colours that could withstand washing. These were exported from the port of Marsulipatnam (on the east coast of India) where, between 1600 and 1800 they formed the basis for one of the largest international trades in textiles ever known.

To increase production, carved wooden blocks replaced pens. In the European markets both printed and painted cottons became known as “Chintz." Today the term refers to almost any textile with floral patterning, but at the time "chintz" denoted a cotton cloth, usually with a white ground, printed or painted with natural dyes.

The European market was not the first, however, the port of Marsulipatnam previously exported kalamkaris to the markets of Safavid Persia. The Persian influence has remained in the floral borders, motifs, and geometric design of the patterning.

Today Marsilaputnam is still a centre of kalamkari block print production. The original natural dye knowledge is still applied and the results are just as beautiful as they were centuries ago. First the cloth is bleached by "dunging" — a treatment with buffalo or goat dung after which the cloth is dried in the sun for a few days. The cloth is mordanted with myrobalan, a tannin bearing nut which grows nearby. Black outlines are printed with an iron solution and areas that will be red are printed with an alum mordant. The various colours are achieved through printing resists, mordants, and then immersion dyeing with different dyes. When using wooden blocks to print, gum is mixed with whatever substance is to be delivered onto the cloth.

Maiwa is dedicated to keeping the art of kalamkari alive. We carry kalamkari bedding, pillows, cushion covers, and we use kalamkari in our clothing designs.